![]()

Free delivery 2 waysQuick and Free Delivery

![]()

Long term GuarantyReturn if you are not satisfied

![]()

transparency ProcessDirect inspection

![]()

Authentic product100% Authentic Product

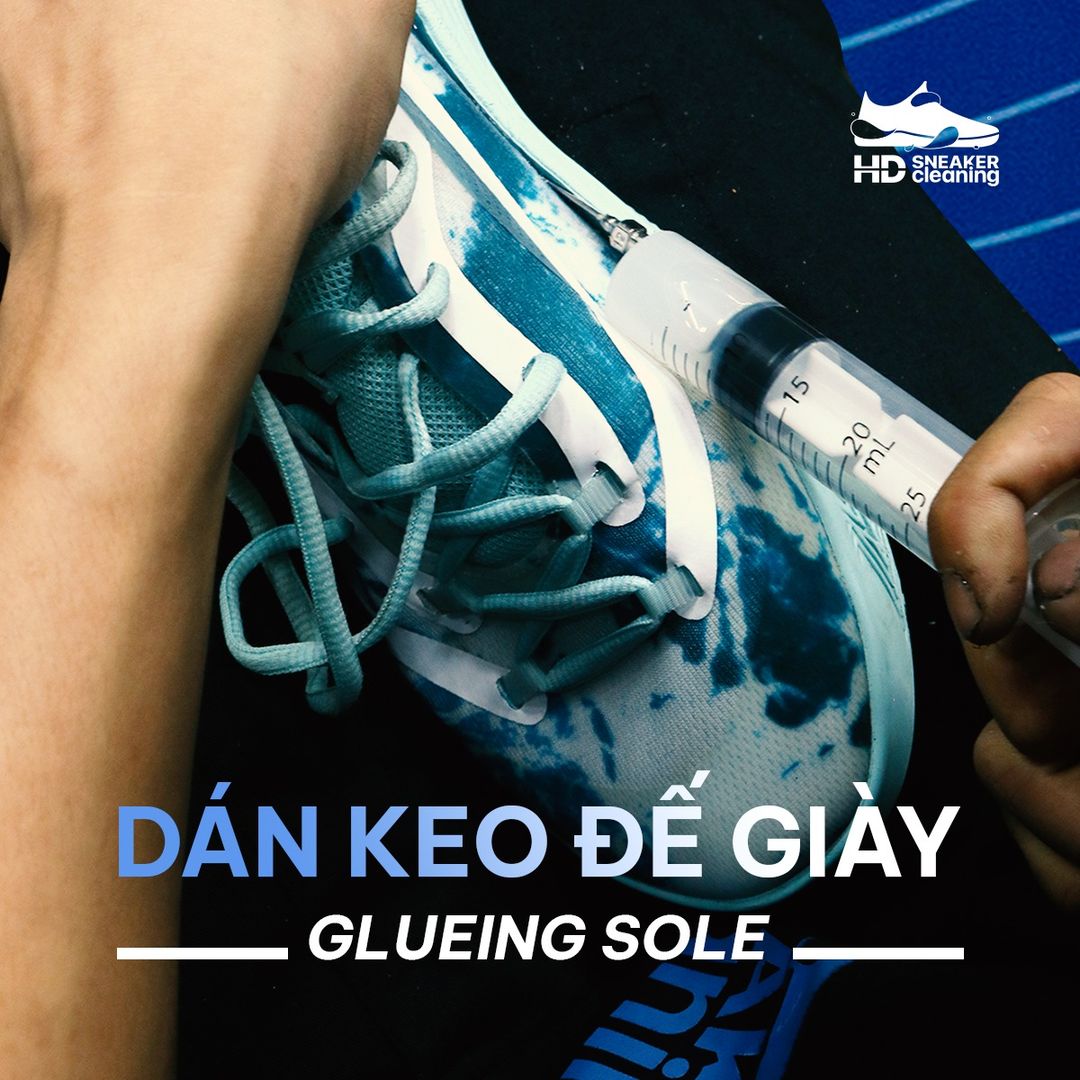

All repair services by HD Services are warranted for 3 months. (Except for shoe glueing service, which is warranted for 2 weeks, and sole stitching/sewing service, which is warranted forever).

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

Slider

class=”accordion”;